Rio Tinto Alcan

Source: Rio Tinto Alcan

Source: Rio Tinto Alcan

Iceland's first plant in Straumsvík went into operation in 1969, which extracts the light alloy from aluminum oxide using fused-salt electrolysis. 185,000 tonnes of aluminum are currently produced here every year. Production is expected to increase to 230,000 tons/year from 2014.

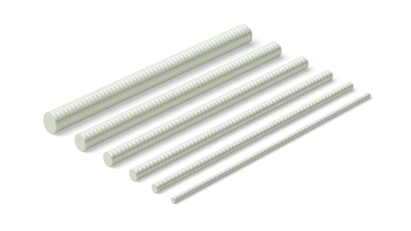

For this purpose, the Canadian owner Rio Tinto Alcan is in the process of renewing and upgrading the transformer station, the rectifiers and the busbars. They supply the electrolysis cells of the smelting plant evenly and reliably with a current of 170,000 to 200,000 amps. Concrete units support the conductors – thick, long aluminum plates – through the busbar rooms and underground tunnels of the Rectifier Stations. A mixed reinforcement comprising the glass-fibre reinforcement Schöck Combar® and steel makes them stable.

If only electrically conductive steel is used in the reinforcement grid of the busbar supports, high induced currents can arise in the rebars within the concrete. The steel bars would thus be heated in a similar way to a saucepan on an induction cooker. They would expand and damage the surrounding concrete, and the construction would no longer be stable.

The non-conductive glass-fibre reinforcement Schöck Combar® provides a reliable and faster solution to avoid inductive currents in modern high voltage power systems.

Rio Tinto Alcan plc

ABB Switzerland, Zürich

Orkuvirki und EV

LTS Logistics Turnkey Service Ltd, Zürich

Summer 2012