Zurich Airport

Image: Flughafen Zürich AG

Image: Thomas Entzeroth

Image: Thomas Entzeroth

Image: Thomas Entzeroth

Image: Schöck Bauteile GmbH

Special reinforcement to enhance flight safety

Manoeuvring aircraft on the ground is no less challenging than when they are airborne; the process is just slower. All larger airports constitute a complex system of take-off and landing runways and taxiways with built-in induction loops that help air traffic control do its job.

Like traffic lights on a road

Ground lights – known as red stop bars – that are clearly visible to pilots mark the “red line” in the truest sense of the word to warn of neuralgic points. Under no circumstances may these lines be crossed without air traffic control’s permission.

Using induction to detect danger

Induction loops in the ground before and after the red lights track aircraft movement. They create an electro-magnetic field that changes as soon as a mass with its own magnetic field – in this case a plane – enters it.

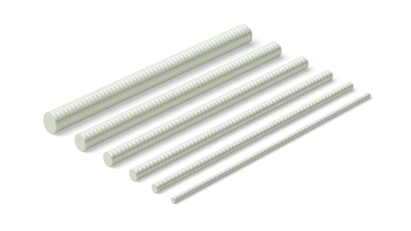

Polymer reinforcement instead of steel

To ensure the functional reliability of this highly sensitive system, the relevant concrete slabs must be permanently and non-magnetically reinforced. During the ongoing work to extend Zurich Airport, the construction manager installed Schöck Combar glass fibre reinforced polymer in these sections. A total of around 25 kilometres of these reinforcing bars are now installed beneath the taxiways at Zurich Airport. Whereas steel would have produced interference in this case, the glass fibre bars are neither magnetic nor magnetisable, non-conductive and moreover non-corroding. A two-part manufacturing process bundles the high-strength glass fibres as compactly as possible before proofing them with special vinyl ester. The result is a resistant and durable material that indirectly even enhances flight safety, as impressively demonstrated at Zurich Airport.