Schöck Isokorb® Thermal Breaks

Balcony Connectors

As extensions of interior floor slabs, traditional balcony slabs conduct heat from the warm building interior into cold exterior environment with the unwanted efficiency of enormous cooling fins. In addition to wasting heat, chilling the interior side of the slab in today's air-tight, higher-humidity buildings can quickly form condensation, causing mold to grow and become airborne months or years before it becomes visible on room surfaces, exposing the developer to significant remediation and personal injury liability.

read more

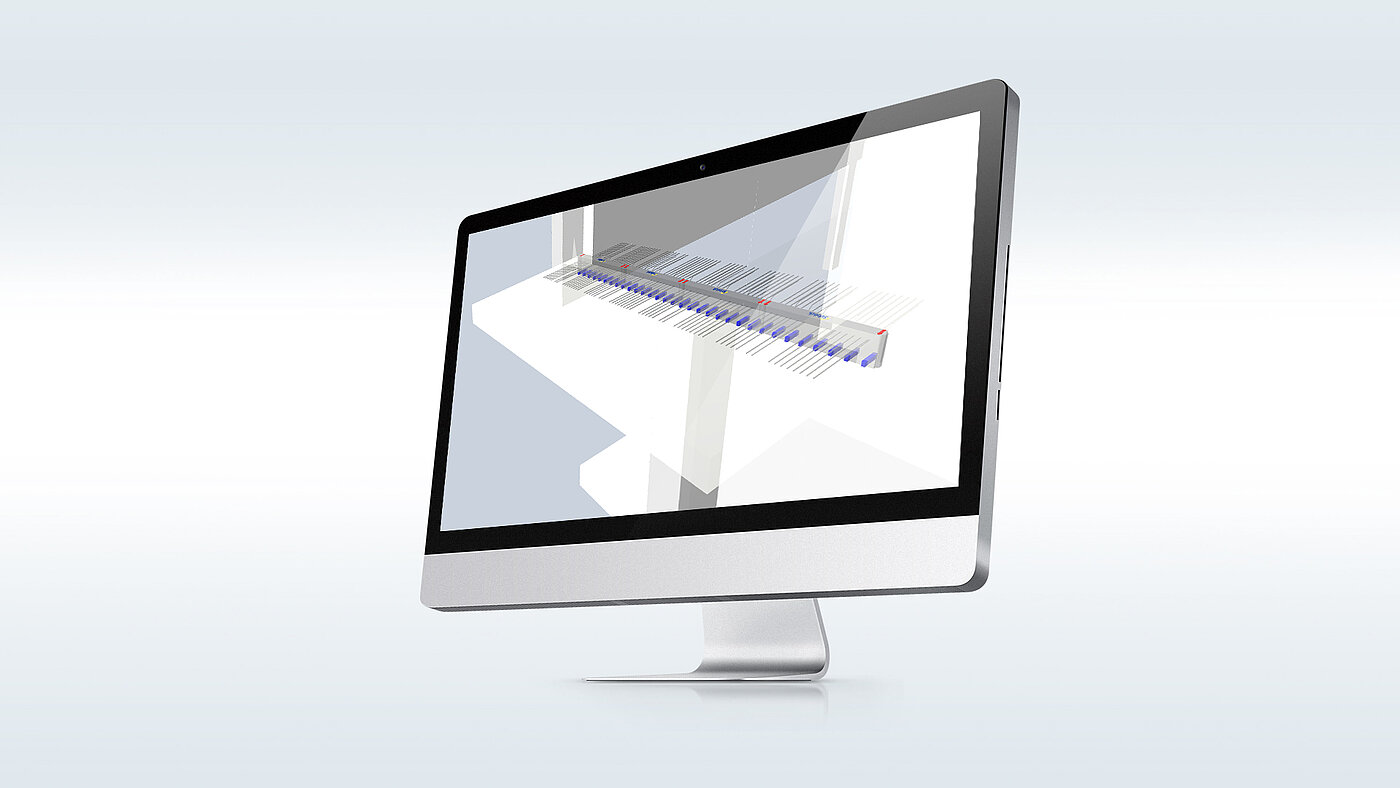

Structural thermal breaks for your balcony connections.

Isokorb® structural thermal break balcony connectors from Schöck can eliminate this problem by providing structural support equivalent to traditional floor slab extensions, and simultaneously insulating the interior floor slab from the exterior balcony slab at the building envelope.

The high-strength cast assembly of our structural thermal break balcony connectors cuts energy waste by up to 90% at the point of building envelope penetration. Eliminating cold interior slabs additionally prevents condensation and mold formation, while offering greater thermal comfort to occupants with interior floors that are up to 34°F / 19°C warmer adjacent to balcony doors and exterior walls.

Whether your balconies are cantilevered or supported, recessed or rounded, Schöck offers the most comprehensive range of structural thermal break products to prevent thermal bridging at your balcony connections.

Explore specific balcony products below or contact us to discuss how using Schöck thermal breaks for balconies on your next project can help protect your building.

Schöck Services.

Ready to assist you.

Schöck North America’s dedicated team is here to support you – ensuring that the solution to thermal bridging proposed for your specific project is the most effective and efficient solution available – every time.

Peace of mind: From initial feasibility studies to provisions of stamped and signed drawings, Schöck’s engineers and technical sales professionals bring expertise and guidance to help you realize your project’s performance goals.

Design aids: If you prefer to design the thermal breaks of your project, Schöck provides readily accessible product drawings, specifications and other technical documentation to assist with your design considerations.

Proven reliability: Schöck has been the industry leader in thermal bridging solutions since we introduced the first commercially available structural thermal break in 1983. With more than 16 million thermal break modules currently installed, we have the know-how and experience to meet your project needs.

For answers to preliminary questions about your project, please contact your Regional Sales Manager. Or if you’re ready for pricing, simply fill out a Project Request Form.