Facts about steel balcony thermal breaks

Thermal requirements

Which thermal performance is required for steel balcony connections?

According UK Building Regulations Part L junction temperature factors, and hence risk of surface condensation, have to be assessed in accordance with section 7.1 and BRE Information Paper IP 01/06. The minimum temperature facture for junction details, e.g. in dwellings and residential buildings, is set at fRSi = 0.75. This only can be verified by 3D thermal analyses.

It is recommended to design structures which provide a temperature factor clearly above the minimum building regulations for more safety with regard to user behavior (e.g. humidity in reality is often higher than according codes) and for more thermal comfort.

Structural requirements

Which structural performance is required for steel balcony connections and is therefore important for the selection of proper solutions?

Load bearing capacity, stiffness and deformation calculations shall be carried out in accordance with UK Building Regulations and are to be verified in large scale testings

Thermal Actions

The lateral displacement of the exterior balcony due to temperature changes shall be tested in large scale test with cyclic lateral displacement. To determine the displacement the permitted distance of the joints has to be assumed. The tested lateral cyclic displacements correspond to a defined temperature spectrum.

Durability

The steel passing through the thermal insulation material shall have an appropriate corrosion protection which is ensured by either stainless steel or a sleeve in stainless around the steel.

Solutions

Which solutions does Schöck provide for steel balconies?

Schöck Isokorb® T type SK for free cantilever concrete-to-steel construction.

Schöck Isokorb® T type S for free cantilever steel-to-steel construction.

What certifications does the steel solutions provide?

Verified structural performance and quality of Schöck Isokorb®

The conformity of Schöck Isokorb® to UK Building Regulations and to the specifics of manufactured structural thermal breaks is independently verified by BBA. The BBA is the UK's major authority offering approval and certification services to manufacturers and installers supplying the construction industry. BBA Approval is recognised by building control, government departments, architects, local authorities, specifiers, and industry insurers like the NHBC, and complement manufacturers own technical data with the BBAs impartial and unbiased information on the performance of the product. The BBA also works closely with regulatory authorities throughout the UK as well, as with housing warranty bodies, to ensure Agrément Certificates are accepted nationwide.

The BBA assessment shows that Schöck Isokorb® provides:

- verified thermal actions considering a working life of minimum 60 years by large scale testings

- verified durability of the materials used

- verified fire protection - Test results have indicated that the products incorporating the fire protection plates are capable of achieving up to 120 minutes loadbearing capacity, 120 minutes integrity and 120 minutes insulation

- verified material and product quality according BBA approval by internal and external quality control

Verified thermal performance of Schöck Isokorb®

To guarantee the accuracy of its current performance values, Schöck has submitted its solutions for independent evaluation by the Oxford Institute for Sustainable Development (OISD), at Oxford Brookes University. One of the UK's largest research institutes dedicated to sustainable development research in the built and natural environments. The results show that Schöck Isokorb® in general provides verifiable thermal performance and compliance with UK Building Regulations Part L.

Schöck Isokorb® T type SK

Schöck Isokorb® T type S

Fire protection

Which fire protection can be reached through thermally broken steel balconies?

Generally, the same fire protection can be reached than for the whole steel balcony.

Installation

What is important to consider during installation?

Since the Schöck Isokorb® T type SK creates an interface between a steel component and a reinforced concrete component, the issue of tolerance is particularly important when installing T type SK. A method of work must be agreed between project engineer, concrete contractor and steel fabricator to ensure acceptable tolerances are met. Consideration should be given to the limitations of the steel fabricator's ability to overcome excessive dimensional differences, without undertaking extra work.

How can potential inaccuracies during installation be compensated?

Design constraints allow a vertical tolerance of 10 mm with the Schöck Isokorb® T type SK. The requisite spacer shims are included with the product.

Horizontal limit deviations for the separation of the T type SK axes must be speci-fied, as must the limit deviations from the alignment. Torsional limits must also be specified.

The use of a template developed on site is highly recommended to ensure dimensionally accurate installation and the correct sitting of the T type SK during the concrete pouring process.

The construction supervisor is responsible for checking the agreed installation accuracy of the T types SK in good time.

Vibration

Are thermally broken steel balconies more prone to vibration?

Architects and structural engineers need to consider a whole host of influencing variables in the development and structural design of steel balconies to make sure the solution is both safe and efficient. When selecting the method of connection to the building slab, the challenge lies in choosing a component that will ensure both an effective thermal break and a structural and design solution that is safe – and all still compliant with the necessary verification requirements.

Generally speaking, lightweight support structures, such as free cantilevered steel balconies, are particularly prone to impermissible vibration when people start to walk, rock about or jump around on them. As designs become ever more lightweight and competitive in terms of total cost, the vibration behaviour of a structure is gaining in importance.

Construction practitioners repeatedly voice their concern that thermally effective insulating elements, such as the Schöck Isokorb® T type SK, make balconies more prone to vibration, while steel balconies connected conventionally with simple pads are more rigid and less susceptible.

Thermally effective connections, such as the Schöck Isokorb® T type SK, are indeed "softer" than traditional connections, due to their material properties. And yet – if planned properly – virtually any balcony geometry can be designed without constraints using Schöck Isokorb® T type SK.

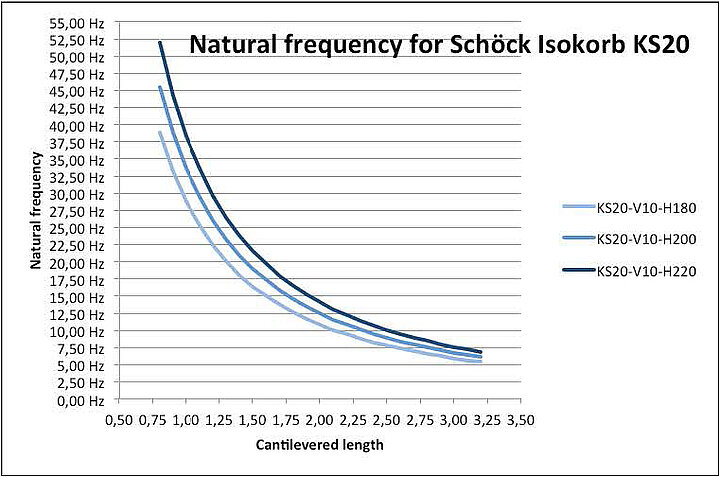

Acceptability of vibrations

Part L defines the limit values for thermal bridges, whereas Eurocode 3 specifies the required verifications, such as vibration, in serviceability limit state. Such verification is usually provided by calculating the natural frequency of the construction. The structural engineer specifies the limit frequency, depending on the utilisation of the structure. Ultimately, the design of the balcony construction and thermal insulating element must ensure that the natural frequency is greater than the limit frequency specified by the structural engineer.

Generally, vibration of floors is considered to be a serviceability issue, primarily related to discomfort, although vibration can also cause minor damage or cracks and can affect sensitive equipment. However, discomfort cannot directly be quantified or scaled. As perception and discomfort vary between humans, no exact limit can be imposed that will guarantee that the structure response will not give rise to adverse comments from occupants throughout its lifetime of use.

Assessment of vibration is therefore not straightforward, but a reasonable and simplified approach is to design structures so that their natural frequency is sufficiently far removed from potential excitation frequencies. Depending on the type and utilisation of the structure, trade literature indicates limit frequencies of between 4 and 7.5 Hz. Experience has shown that taking a limit frequency of 7.5 Hz for steel balconies not only eliminates the possibility of impermissible vibration; it also enables the design of cost efficient structures.

The first natural frequency can thus be calculated for a cantilever beam as follows:

The calculation produces the total spring stiffness kges from the distortion of the connection and as a result of the bending curve of the balcony construction. The total mass mges = mg + mq results from the dead load of the construction (steel beam, covering layer, railing etc.) and the percentage of live load to be expected. This share is assumed to be 30% of the total live load, corresponding to the quasi-permanent load combination used for the serviceability limit state design situation.

Natural frequencies of steel balconies thermally broken by Schöck Isokorb® T type SK

Schöck Isokorb® T type SK for concrete-steel connections is a thermal element with 80 mm insulation that ensures effective thermal breaks. The component can be pre-fabricated to a large degree at the steelworks, thus reducing the time needed to assemble on site to a minimum. Since it can bear heavy loads, it can be easily used to resolve the technical and structural issues of designing modern balconies. Normally, the elements are exposed to dead loads, and transfer moments, shear forces and horizontal forces parallel to the edge of the slab in the case of cantilever steel balconies with thermally broken connection to a concrete slab. The element is 180 mm wide. It is between 180 mm and 280 mm high for flexible adjustment to differing slab thicknesses. The insulating layer is 80 mm thick.

In order to assess how prone balconies with thermal separation provided by Schöck Isokorb® T type SK are to vibration, the natural frequencies of the structures were calculated under consideration of numerous geometric and material variables.

The result: The natural frequencies of normal balcony constructions are still above the recommended limit frequencies, even when using and considering Schöck Isokorb® T type SK.

Recommendations for planning and designing steel balconies

The following parameters influence the natural frequency and, as such, the vibration behaviour of free cantilever steel balconies. Particular attention should therefore be paid to them when planning and designing thermally broken steel balconies:

- Balcony geometry, especially the cantilever length and spacing between the connections

- Rigidity and proper execution of the stub bracket, especially on stepped thresholds

- Sufficient transverse rigidity of the balcony construction

- Incorporation of the stiffness of the chosen thermal insulating element into the planning process

Schöck can help with vibration analysis, and offers a comprehensive service portfolio to support proper and safe planning of thermally broken steel balconies. A team of engineers equipped with calculation programs and technical literature is available to answer questions.