Sustainable due to energy-efficient façades

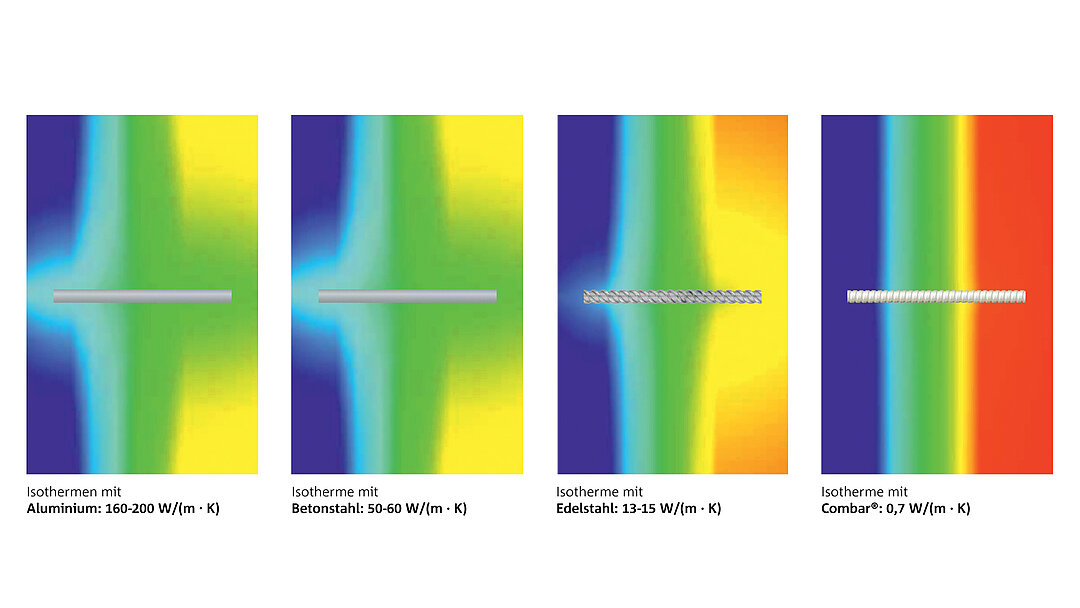

Owing to the requirements of the Energy Saving Ordinance (EnEV), the demand for thermal-bridge-free products is increasing. Aluminium, reinforcing steel or stainless steel fastenings in core-insulated concrete façades and back-ventilated curtain wall façades (VCWF) cause thermal bridges. To satisfy the requirements of EnEV, façade fixtures that reduce the heating energy demand are required.

Energy-efficient with aesthetic appeal

Isolink® has been specially developed for two types of façade:

Every type of core-insulated concrete wall and façade can be isolated without thermal bridges with Isolink® and can also achieve high-quality surface finishes up to fairfaced concrete class 4.

Furthermore, Isolink® can be used with back-ventilated curtain wall (VCW) façades to establish a thermal-bridge-free fixture. This type of façade not only has aesthetic appeal and has enormous design flexibility, it is also a low-maintenance cost-effective construction system.

Fastening façades in an energy-efficient manner

Schöck Isolink®

The Schöck Isolink® thermally-isolated connection is used to secure façades without thermal bridges to achieve the required energy efficiency. This is made possible by using Combar®, a glass-fibre composite material with an extremely low thermal conductivity.

Satisfy requirements with innovative material

Combar®, the glass-fibre composite material developed and manufactured in-house by Schöck, was launched on the market in 1997. This product has an exceptionally high percentage of glass fibres embedded in a plastic resin matrix, and the highly specialised innovative production process, Combar® has exceptional material characteristics. This makes it a superior alternative to conventional steel materials in many applications.

Its extremely low thermal conductivity makes it particularly effective when used in insulating layers.

The Schöck Isolink® façade fixture is made of glass fibre composite material and ensures thermal-bridge-free attachment of façades. Thermographic studies confirm the superior performance of the glass-fibre composite material compared to steel materials with a thermal conductivity of only 0.7 W/(mK).